News

2021

Data Driven Dialog – Fraunhofer Competence Center Automotive

In the automotive sector, Fraunhofer is developing visual-interactive solutions for the next generation of all phases of the automobile product life cycle—from the development process and design reviews to technical simulations and quality control for the production of individual components. This way, Fraunhofer aims to change the mobility of the future, e.g., via computer vision solutions for automonous driving, via data analysis and visualisation for engineering or via simulation and evaluation of behaviour and driving fun of drivers in virtual reality. Fraunhofer invited key stateholders to participate in this networking event on October 13, 2021.

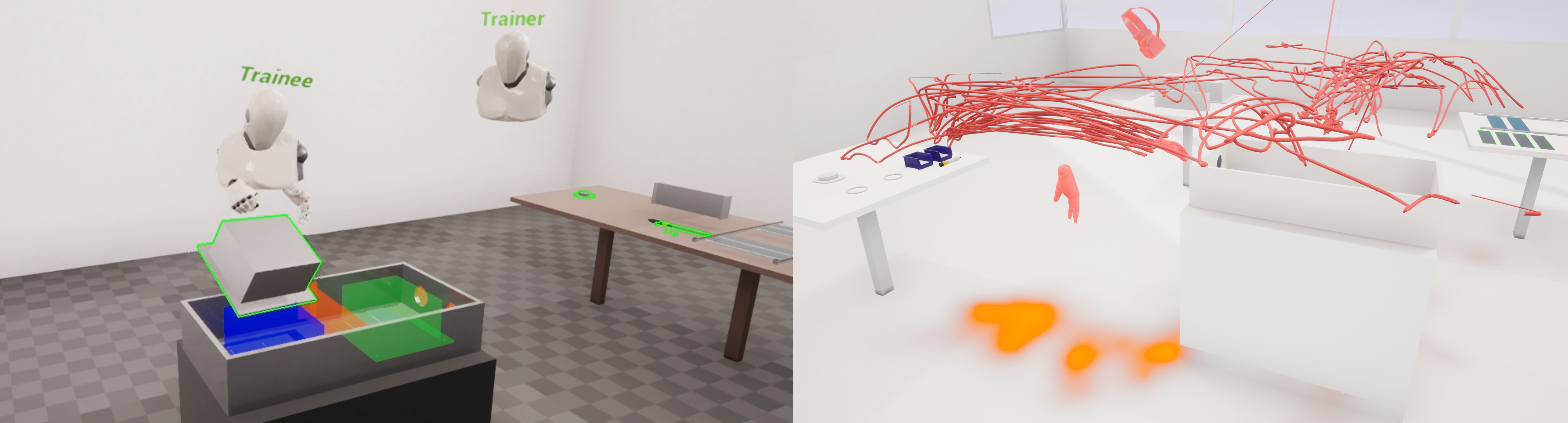

An example scenario of our assembly training at the event presented virtual reality and its affordances for the automotive sector.

Cyberworlds 2021

We have presented our work on A System for Collaborative Assembly Simulation and User Performance Analysis at Cyberworlds2021.

We have uploaded the paper presentation to the CGV Youtube Channel

2020

Computer Graphics International 2020

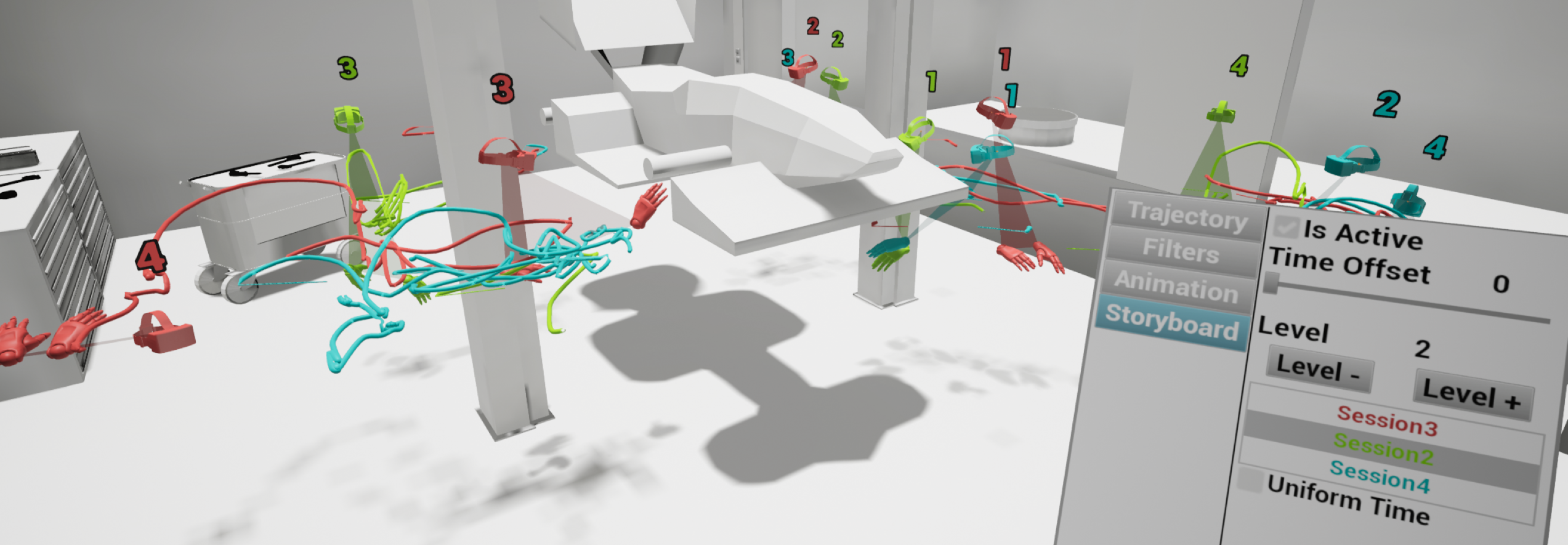

We have presented our work on the Immersive analysis of user motion in VR applications at Computer Graphics International 2020.

The publication and a demo video can be found on the publisher's homepage

Cyberworlds 2020

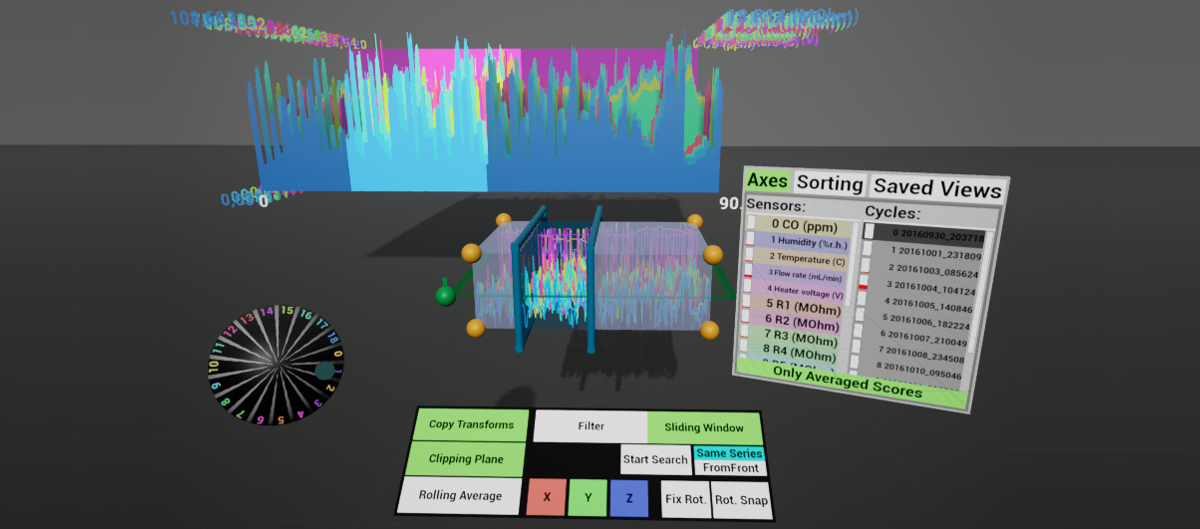

We have presented our work on the Immersive Analytics of Anomalies in Multivariate Time Series Data with Proxy Interaction at Cyberworlds2020.

We have uploaded the paper presentation to the CGV Youtube Channel

2019

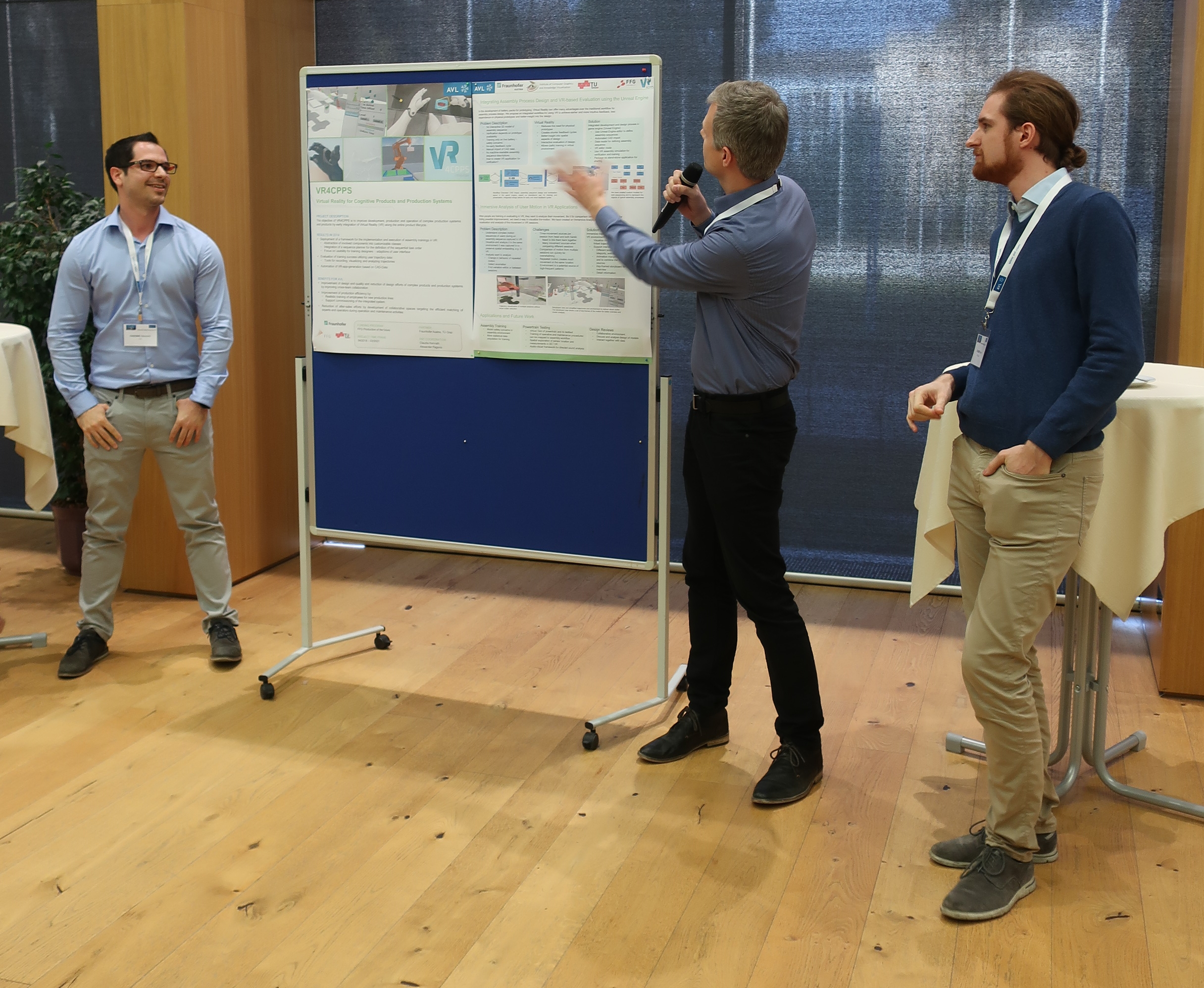

AVL Networking Day

We have presented our preliminary works at this years AVL Research Networking Day. The day was filled with compelling keynote talks and interesting poster presentations, showing the extensive work by researchers and AVL around the globe.

Fraunhofer Sommerfest

Numerous guests from business and science as well as researchers from Fraunhofer Austria celebrated the traditional Fraunhofer Sommerfest together in the garden of the Institute of Management Sciences at Vienna University of Technology.

The exchange of knowledge and best-practice examples between research and industry as well as the exchange between industrial partners is a significant contributor to keeping Austria's businesses ready for the digital future. To this end, several short talks concerning innovative topics were held at the event.

The Visual Computing division presented, among other things, the VR4CPPS project's progress towards VR applications for virtual trainings at AVL.

First Workshop of the Year

Feeling refreshed after the holidays, the VR4CPPS team held the first workshop of the year to discuss this years goals. We are looking forward to a year filled with new ideas and results to further our goals. Our intermediate goals include the analysis of expert feedback received during previous interviews and a use case for training and its quantification.

2018

ManusVR Gloves

Since the recent increase in VR accessibility, the development of new and affordable data gloves for virtual environments has been ongoing. We want to use these VR gloves to increase the immersion of our virtual environments as they allow us to use more intuitive and natural interactions. The additional tracking of the hand also increases the amount of available information concerning the movement of the hand and fingers, which allows for a more comprehensive analysis of users' movements.

To test their effectiveness, we have acquired VR gloves that track the movement of all fingers and are able to give feedback through a vibrating motor. Paired with positional tracking of the arm, they can accurately represent the hands of users.

ManusVR HomepageProject Statement

The automotive industry is in deep change due to disruptive new technologies like e.g. increased cognitive capabilities of vehicles, and increased connectivity with the environment. Also, expectations towards the design and production of innovative powertrain systems as well as related test systems and test facilities are rising. Especially, the alignment of instrumentation and test technology with innovative new powertrain technology is challenging. The goal of the research project VR4CPPS (Virtual Reality for Cognitive Products and Production Systems) is to improve development, production and operation of complex production and test systems by early integration of Virtual Reality (VR) technology. We focus on the improvement of the design quality by enhanced cross-team collaboration methods, and on improvement of production efficiency by VR-based training of technicians for new production lines. Furthermore, we focus on the reduction of after-sales efforts through the development of virtual spaces for efficient collaboration of experts and operators during operation and maintenance activities.

Main technological challenges include the efficient creation of a digital twin, the development of a distributed VR environment improving collaboration across skills and geographical locations, and methods for interactive visualization and analysis of (non-geometric) data in VR, including measurement data, metadata and process data.

The complementary VR4CPPS consortium consists of AVL as industry partner, and Fraunhofer Austria as well as the TU Graz Institute of Computer Graphics and Knowledge Visualization as scientific partners. VR4CPPS is funded by the FFG within the initiative FTI Production of the Future.